The Future of Bathroom Cabinet Manufacturing: What to Expect in 2024

The bathroom cabinet manufacturing industry is on the brink of significant transformations. As we move into 2024, advancements in technology, sustainability practices, and design trends are set to redefine the landscape. This comprehensive blog explores the future of bathroom cabinet manufacturing, offering detailed insights into key trends and innovations that will shape the industry. Whether you are a manufacturer, dealer, or end-user, understanding these trends is crucial for staying competitive and meeting evolving customer expectations.

What is the Current State of Bathroom Cabinet Manufacturing?

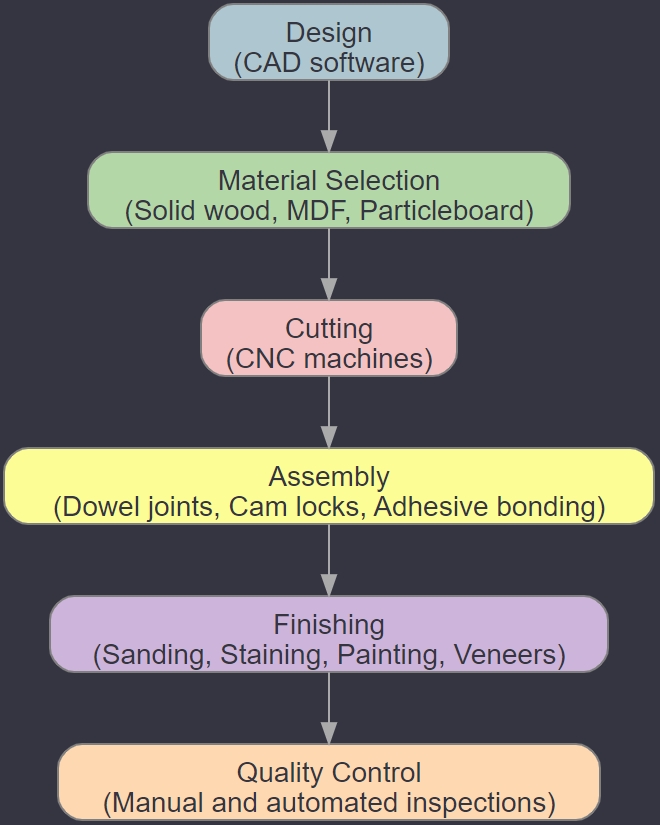

Bathroom cabinet manufacturing today is characterized by a blend of traditional craftsmanship and modern technology. Manufacturers utilize a variety of materials, including solid wood, MDF (medium-density fiberboard), particleboard, and metal. The manufacturing process involves several stages, such as design, material selection, cutting, assembly, finishing, and quality control.

Understanding Today's Bathroom Cabinet Manufacturing Processes

1. Design: The design phase involves creating detailed blueprints and 3D models of the cabinet. Advanced CAD.

2. Material Selection: Selecting the right materials is crucial for durability and aesthetics. Solid wood, such as oak and maple, is popular for its strength and natural beauty. MDF and PVC are cost-effective alternatives that offer flexibility in design.

3. Cutting: CNC (computer numerical control) machines are commonly used for cutting materials with high precision. These machines follow digital instructions to produce accurate cuts and shapes.

4. Assembly: The cut pieces are then assembled using various techniques, such as dowel joints, cam locks, and adhesive bonding. The assembly process ensures that the cabinet is sturdy and well-constructed.

5. Finishing: The finishing process involves sanding, staining, painting, or applying veneers to enhance the cabinet's appearance. High-quality finishes not only improve aesthetics but also protect the wood from moisture and wear.

6. Quality Control: Quality control is an ongoing process that involves inspecting each stage of production. Manufacturers use a combination of manual inspections and automated systems to detect defects and ensure that the final product meets industry standards.

Challenges in the Bathroom Cabinet Manufacturing Industry

Despite advancements, manufacturers face several challenges that impact production and profitability. These challenges include:

Supply Chain Disruptions: The global supply chain has been significantly affected by events such as the COVID-19 pandemic, geopolitical tensions, and natural disasters. These disruptions can lead to delays in material delivery, increased costs, and production halts.

Rising Material Costs: The cost of raw materials, such as wood, metal, and adhesives, has been on the rise. Fluctuating prices can affect profit margins and force manufacturers to find cost-effective alternatives without compromising quality.

Demand for Faster Production Times: Customers expect quick turnaround times for their orders. Meeting these expectations requires optimizing production processes and investing in advanced machinery and technology.

How Will Technology Shape Bathroom Cabinet Manufacturing in 2024?

Automation and Robotics

The integration of automation and robotics in manufacturing processes is expected to increase efficiency and precision. Automated assembly lines and robotic arms can handle repetitive tasks with greater accuracy, reducing production time and costs. Key areas where automation and robotics will make an impact include:

Material Handling: Automated systems can efficiently handle and transport materials within the factory, reducing the risk of damage and ensuring timely delivery to different production stages.

Cutting and Shaping: CNC machines, equipped with advanced software, can perform intricate cutting and shaping tasks with high precision. This reduces material waste and enhances the quality of the final product.

Assembly: Robotic arms can assemble cabinet components with consistent accuracy, ensuring strong joints and uniform construction. This minimizes human error and speeds up the assembly process.

Finishing: Automation in finishing processes, such as sanding, staining, and painting, ensures uniform application and reduces the risk of defects. Automated sprayers and sanders can cover large surfaces quickly and evenly.

Artificial Intelligence

AI is playing a crucial role in design optimization and quality control. AI algorithms can predict design trends, optimize material usage, and detect defects early in the production process, ensuring higher quality products. Key applications of AI in bathroom cabinet manufacturing include:

Design Optimization: AI-powered design software can analyze customer preferences and market trends to create optimized designs that are both functional and aesthetically pleasing. This reduces the time spent on manual design iterations and increases customer satisfaction.

Predictive Maintenance: AI can monitor machinery and equipment for signs of wear and tear, predicting maintenance needs before failures occur. This minimizes downtime and extends the lifespan of equipment.

Quality Control: AI-based image recognition systems can inspect cabinet components for defects such as scratches, dents, and misalignments. These systems can identify issues that may be missed by human inspectors, ensuring consistent quality.

Supply Chain Management: AI can analyze supply chain data to predict demand, optimize inventory levels, and identify potential disruptions. This helps manufacturers maintain a smooth production flow and reduce costs.

Emerging Technologies

Emerging technologies such as 3D printing and augmented reality (AR) are also making their way into the manufacturing sector. These technologies offer new possibilities for customization, prototyping, and customer engagement.

3D Printing: 3D printing allows for rapid prototyping and customization. Manufacturers can quickly produce prototypes of new designs, test their functionality, and make necessary adjustments before mass production. 3D printing also enables the creation of complex shapes and intricate details that are difficult to achieve with traditional methods.

Augmented Reality: AR can be used for virtual design consultations and quality inspections. Customers can use AR apps to visualize how different cabinet designs will look in their bathrooms, making it easier to make informed decisions. AR can also assist quality inspectors by overlaying digital guidelines on physical components, ensuring precise measurements and alignment.

What Are the Trends in Bathroom Cabinet Design for 2024?

Popular Design Trends

Design trends for 2024 are leaning towards minimalism, with clean lines and neutral color palettes. There's also a growing preference for multifunctional cabinets that maximize storage while maintaining aesthetic appeal. Key design trends to watch include:

Minimalism Bathroom Cabinet:

Minimalist designs focus on simplicity, functionality, and elegance. Cabinets with sleek, unadorned surfaces, hidden handles, and integrated storage solutions create a clean and uncluttered look.

Neutral colors, such as white, gray, and beige, are popular choices for bathroom cabinets. These colors create a calming and timeless atmosphere that complements various bathroom styles.

Cabinets with built-in features, such as pull-out organizers, adjustable shelving, and integrated mirrors, offer enhanced functionality and convenience. These designs maximize storage space and keep the bathroom organized.

Sustainability And Eco-Friendly Materials

Sustainability is a significant trend, with manufacturers increasingly using recycled materials and water-based finishes. Bamboo and reclaimed wood are becoming popular choices due to their environmental benefits. Key considerations for sustainable design include:

Recycled Materials: Using recycled materials, such as reclaimed wood and recycled plastic, reduces the demand for virgin resources and minimizes waste. These materials also add a unique character to the cabinets.

Water-Based Finishes: Water-based finishes are eco-friendly alternatives to solvent-based finishes. They emit fewer volatile organic compounds (VOCs), improving indoor air quality and reducing environmental impact.

Bamboo: Bamboo is a fast-growing, renewable resource that is durable and versatile. It is an excellent choice for eco-friendly bathroom cabinets, offering strength and a natural aesthetic.

Customization Options

Consumers are seeking personalized solutions, leading to an increase in customizable cabinet options. From adjustable shelving to bespoke finishes, manufacturers are offering a range of customization possibilities to meet diverse needs. Key customization options include:

Adjustable Shelving: Cabinets with adjustable shelves allow users to modify the storage layout to accommodate different items. This flexibility ensures that the cabinet meets the specific needs of the user.

Bespoke Finishes: Custom finishes, such as unique stains, paints, and veneers, enable customers to create a one-of-a-kind look. Manufacturers can offer a variety of finishes to match different styles and preferences.

Tailored Dimensions: Custom-sized cabinets can be designed to fit specific spaces, ensuring a perfect fit and maximizing storage. This is particularly useful for bathrooms with unconventional layouts or limited space.

How Can Factories Meet the Growing Demand for Quality and Customization?

Maintaining High Quality in Mass Production

To ensure quality in large-scale production, factories are adopting rigorous quality control measures. This includes regular inspections, standardized procedures, and the use of high-quality materials. Key strategies for maintaining quality include

2024 Bathroom Cabinet Manufacturing Report