The Role of OEM and ODM in Bathroom Vanity Production

1. What are Bathroom Vanity OEM and ODM?

When exploring the world of bathroom vanity production, two terms frequently arise: OEM and ODM. OEM stands for Original Equipment Manufacturer, where a company produces products designed by another company and sells them under that company’s brand. ODM stands for Original Design Manufacturer, where the manufacturer designs and produces the product, which is then branded and sold by another company. Both play pivotal roles in the manufacturing landscape, especially in the production of bathroom vanities.

Importance of OEM and ODM in Bathroom Vanity Production

In the bathroom vanity industry, OEM and ODM manufacturers are crucial. They offer flexibility, customization, and innovation, enabling businesses to bring high-quality, unique products to market efficiently. Understanding their roles can help you make informed decisions, whether you're a supplier, dealer, or end consumer.

2. What is OEM in Bathroom Vanity Production?

Definition of OEM

OEM, or Original Equipment Manufacturer, involves producing bathroom vanities designed by another company. The manufacturer follows the specifications provided, ensuring the final product meets the brand’s standards and requirements.

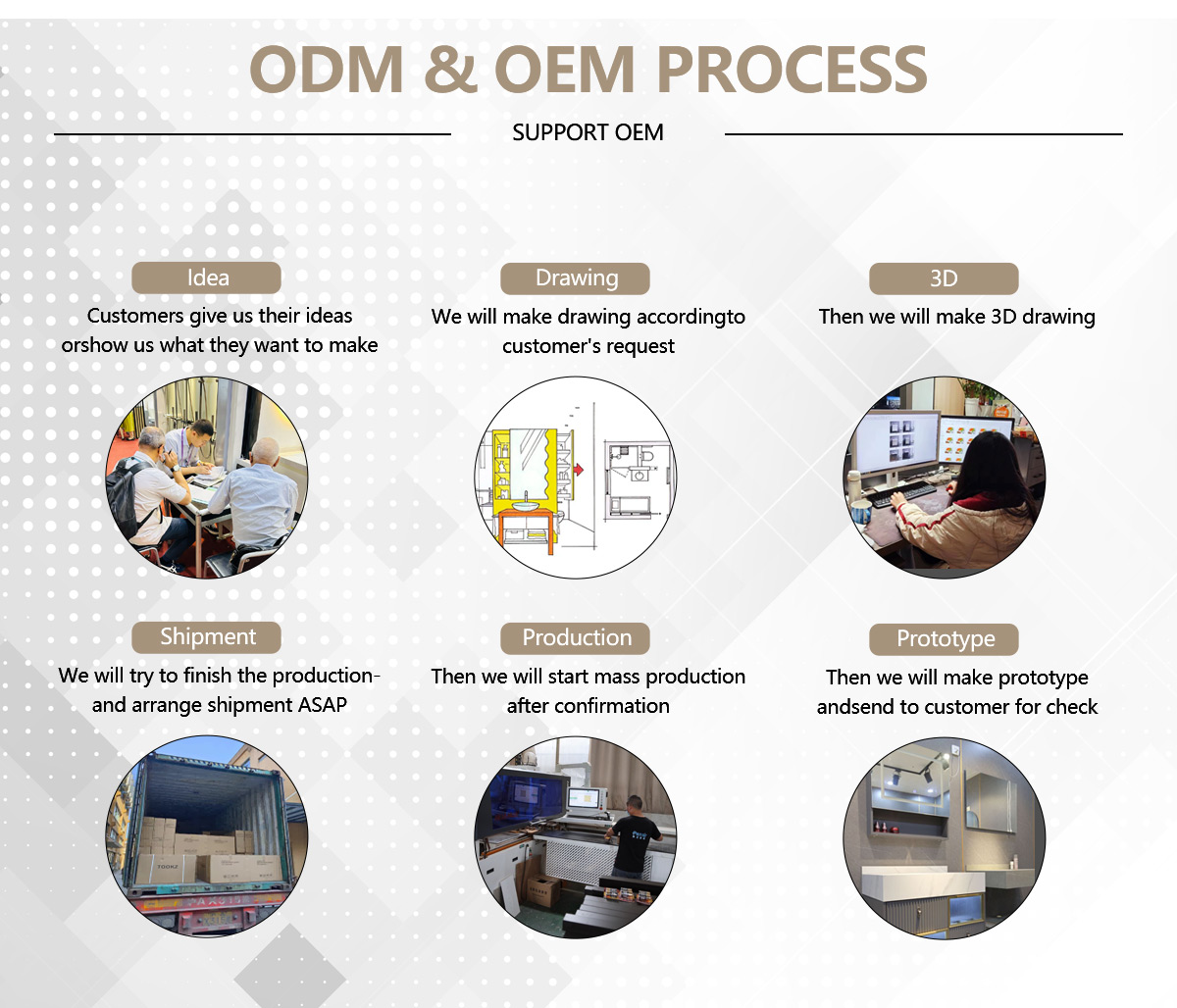

How OEM Bathroom Vanity Production Works

The OEM process begins with the client providing detailed design specifications to the manufacturer. These include dimensions, materials, finishes, and other essential features. The manufacturer then produces the vanities according to these guidelines, often using advanced machinery and skilled labor to ensure precision and quality.

Benefits of OEM for Manufacturers and Customers

OEM offers several advantages:

Customization: Brands can offer unique products without investing in manufacturing facilities.

Cost-Effectiveness: Outsourcing production can reduce costs associated with in-house manufacturing.

Focus: Companies can focus on marketing and sales while the OEM handles production.

Scalability: Manufacturers can quickly scale production to meet demand.

3. What is ODM in Bathroom Vanity Production?

Definition of ODM

ODM, or Original Design Manufacturer, takes the process a step further by designing and producing bathroom vanities. The client then brands and sells these products as their own.

How ODM Bathroom Vanity Production Works

In ODM production, the manufacturer takes on the responsibility of designing the product. This process involves:

Market Research: Identifying trends and consumer needs.

Design and Development: Creating prototypes and refining designs.

Production: Manufacturing the final product at scale.

Advantages of ODM for Customization and Innovation

ODM is beneficial for companies seeking unique products without investing in R&D:

Innovation: Manufacturers often have insights into the latest trends and technologies.

Speed to Market: ODM can accelerate the time from concept to product availability.

Reduced Risk: The manufacturer assumes the risk of product development.

4. How to Choose Between OEM and ODM for Bathroom Vanity Production

Key Differences Between OEM and ODM

Choosing between OEM and ODM depends on your business needs:

Control: OEM allows more control over the design, while ODM provides ready-made designs.

Cost: ODM can be cost-effective for new designs, while OEM might be better for specific customizations.

Speed: ODM can be faster for bringing new designs to market.

Factors to Consider When Choosing OEM or ODM

When deciding, consider these factors:

Budget: Evaluate the costs of each approach.

Timeline: Consider how quickly you need to bring products to market.

Customization Needs: Determine the level of customization required.

5. Why Quality Control is Crucial in OEM and ODM Bathroom Vanity Production

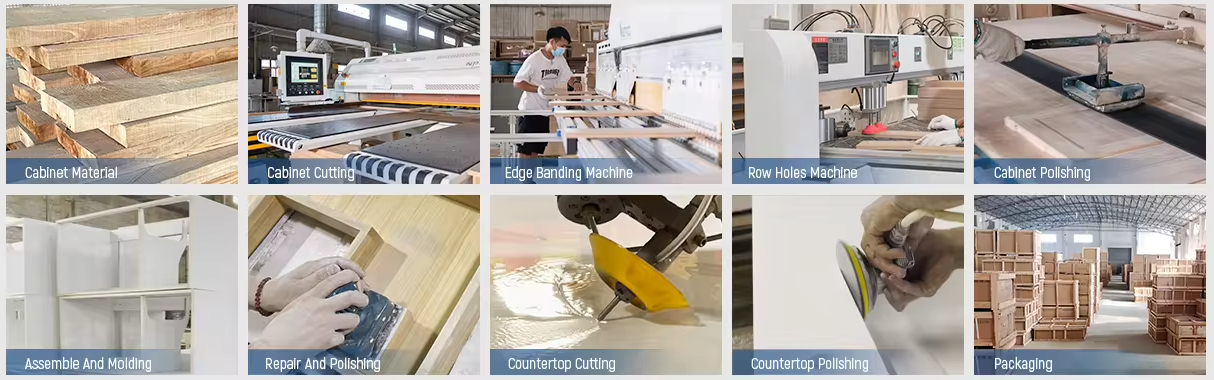

Quality Control Measures in Bathroom Vanity Production

Ensuring high-quality production involves:

Inspections: Regular checks during various production stages.

Testing: Assessing durability, safety, and functionality.

Certifications: Compliance with industry standards and regulations.

Ensuring High Standards in OEM and ODM Processes

Both OEM and ODM manufacturers must maintain stringent quality control:

Supplier Audits: Evaluating material suppliers for quality.

Process Controls: Monitoring manufacturing processes for consistency.

Final Inspections: Thorough checks before shipping.

Common Quality Issues and How They Are Addressed

Quality issues can arise, such as:

Material Defects: Using high-grade materials and thorough inspections.

Production Errors: Implementing strict process controls and employee training.

Design Flaws: Extensive testing and prototype evaluations.

6. How OEM and ODM Impact the Cost of Bathroom Vanity Production

Cost Factors in OEM and ODM Production

Several factors influence costs:

Materials: Higher quality materials increase costs but ensure better products.

Labor: Skilled labor is essential but can be expensive.

Scale: Larger production runs often reduce per-unit costs.

Balancing Quality and Cost in Bathroom Vanity Production

Finding the right balance involves:

Material Choices: Opting for cost-effective yet durable materials.

Efficiency: Streamlining production processes to reduce waste.

Negotiation: Working with suppliers and manufacturers to get the best prices.

Tips for Reducing Costs Without Compromising Quality

Bulk Orders: Larger orders can reduce costs per unit.

Supplier Relationships: Building strong relationships with suppliers can lead to better deals.

Process Optimization: Continuously improving manufacturing processes to enhance efficiency.

7. What to Look for in an OEM or ODM Bathroom Vanity Manufacturer

Key Traits of a Reliable Bathroom Vanity Manufacturer

When selecting a manufacturer, consider these traits:

Experience: Years in the industry and proven track record.

Capabilities: Ability to meet your production needs and specifications.

Quality Control: Robust quality assurance processes.

Questions to Ask Potential Manufacturers

Ensure you choose the right partner by asking:

Production Capacity: Can they meet your volume requirements?

Lead Times: How quickly can they produce and deliver your products?

Quality Assurance: What are their quality control measures?

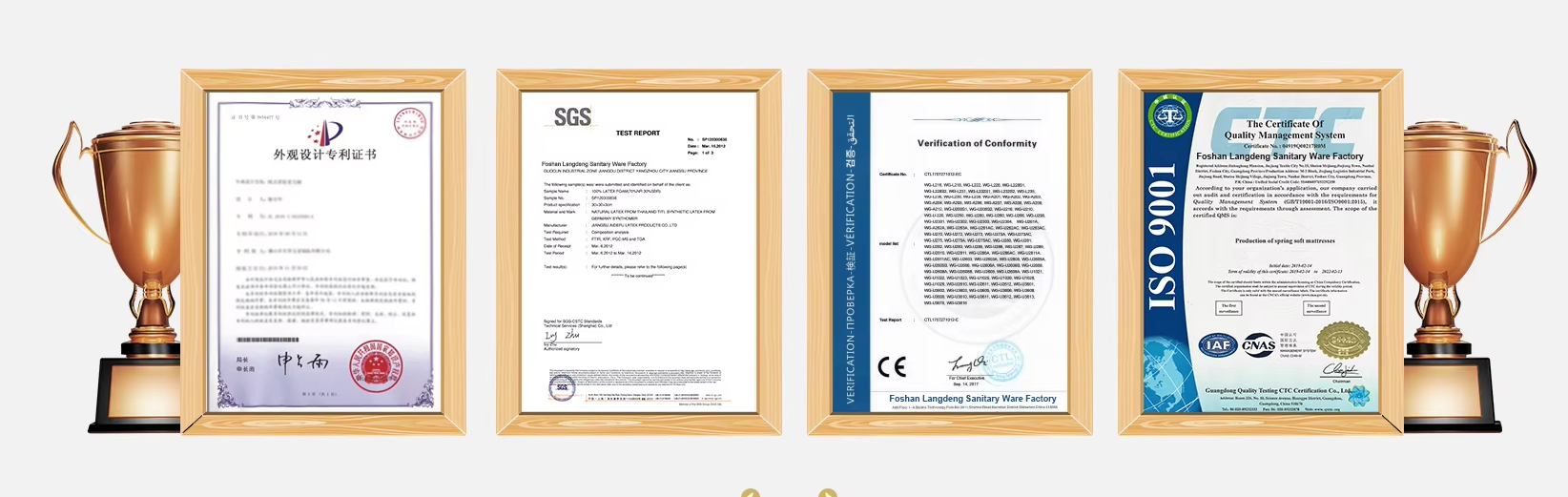

How to Verify Manufacturer Credentials and Capabilities

References: Ask for references from other clients.

Certifications: Check for relevant industry certifications.

Site Visits: If possible, visit the manufacturing facilities.

8. How OEM and ODM Manufacturers Adapt to Market Trends in Bathroom Vanity Production

Current Trends in Bathroom Vanity Design

Trends impacting the industry include:

Minimalism: Sleek, simple designs with clean lines.

Sustainability: Eco-friendly materials and processes.

Technology: Smart features integrated into vanities.

How OEM and ODM Manufacturers Stay Ahead of Trends

Manufacturers stay competitive by:

Innovation: Investing in R&D to develop new products.

Flexibility: Adapting quickly to market changes.

Collaboration: Working closely with clients to understand their needs.

Case Studies of Trend-Adaptive Bathroom Vanity Production

Examples of successful adaptations:

Eco-Friendly Designs: Manufacturers introducing sustainable vanities in response to consumer demand.

Smart Vanities: Integrating technology like touchless faucets and smart mirrors.

9. The Future of OEM and ODM in Bathroom Vanity Production

Emerging Technologies in Bathroom Vanity Manufacturing

Future technologies include:

3D Printing: Creating intricate designs and prototypes.

AI and Automation: Enhancing production efficiency and quality control.

Smart Materials: Using materials that offer advanced features like self-cleaning surfaces.

Predictions for the Future of OEM and ODM Production

Expectations for the future:

Increased Customization: More tailored solutions for customers.

Sustainability: Greater focus on eco-friendly production.

Technological Integration: Advanced technologies becoming standard in vanities.

How Manufacturers Are Preparing for Future Trends

Preparation strategies:

Investing in Technology: Upgrading equipment and software.

Training Workforce: Ensuring employees are skilled in new technologies.

Market Research: Continuously monitoring trends to stay ahead.

10. Conclusion

Recap of the Role of OEM and ODM in Bathroom Vanity Production

OEM and ODM play vital roles in the bathroom vanity industry by providing customized and innovative solutions that meet market demands. Understanding their differences and advantages can help businesses make informed decisions.

Final Thoughts on Choosing the Right Manufacturer

Selecting the right manufacturer involves evaluating their experience, capabilities, and quality control measures. By partnering with a reliable OEM or ODM manufacturer, you can ensure high-quality bathroom vanities that meet your specifications and market needs.

2024 New Design for Bathroom Vanity

Contact Ayala Vanity Manufacturer to Get More New Designs